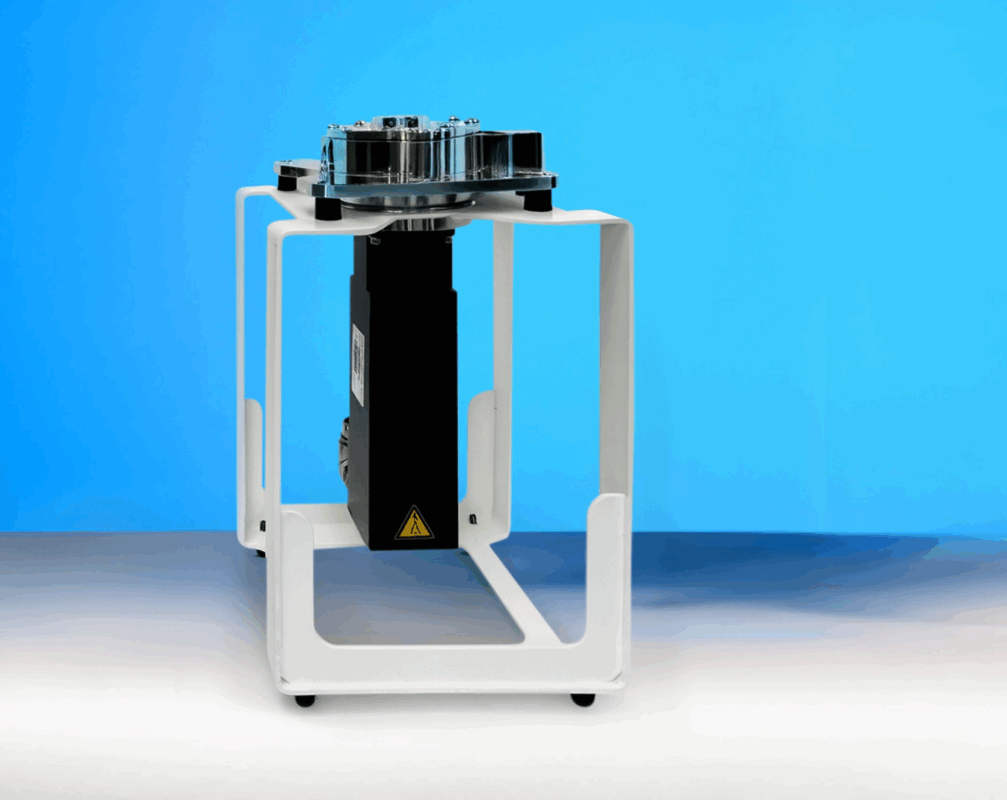

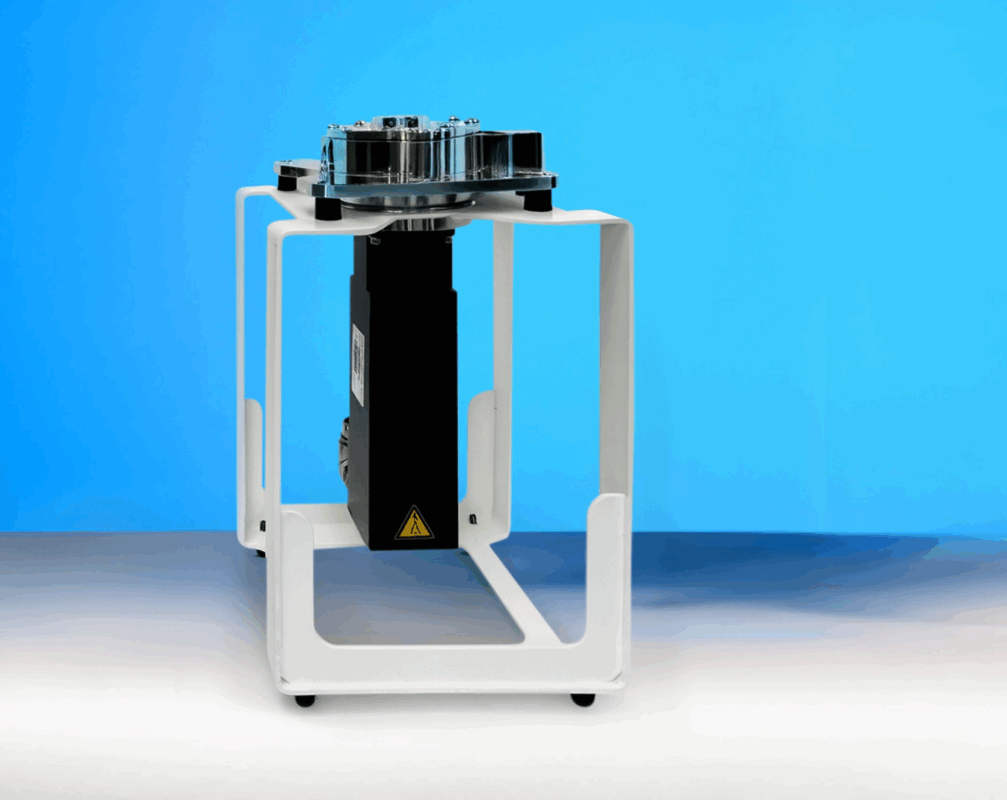

SpinPro R1

Volume: 5 mL

Stages: 1

Disc speed: 6000 rpm

Max. pressure: 10 barg

Max. temperature: 140 °C

Material: Hastelloy

SpinPro reactors are unique as they grant independent control over both mixing intensity and production capacity. The rapidly rotating disc in a very narrow housing generates very high shear forces and extremely intense turbulence. This will shorten production times from many hours in batch to mere seconds in flow.

Contact usSpinPro technology is well suited for multiphase chemistry:

Key Features are:

Organometallic Chemistry

Read more about the benefits of butyl-lithium chemistry performed in SpinPro reactors.

Nitration

Easy to scale up and safe. Flexible skid for production operational.

Halogenation

Chlorination, gas / liquid reaction using Tantalum SpinPro reactor.

Controlled Emulsification

Read more about precise and accurate emulsification in the SpinPro in this post.

The table below illustrates the SpinPro Reactor configurations. A range of options is available; higher pressures, higher temperatures, ATEX and GMP. Several setups, complete with dosing systems, are available for rent. Flowid offers process development support to assist you with continuous processing. For more information contact Flowid.

Volume: 5 mL

Stages: 1

Disc speed: 6000 rpm

Max. pressure: 10 barg

Max. temperature: 140 °C

Material: Hastelloy

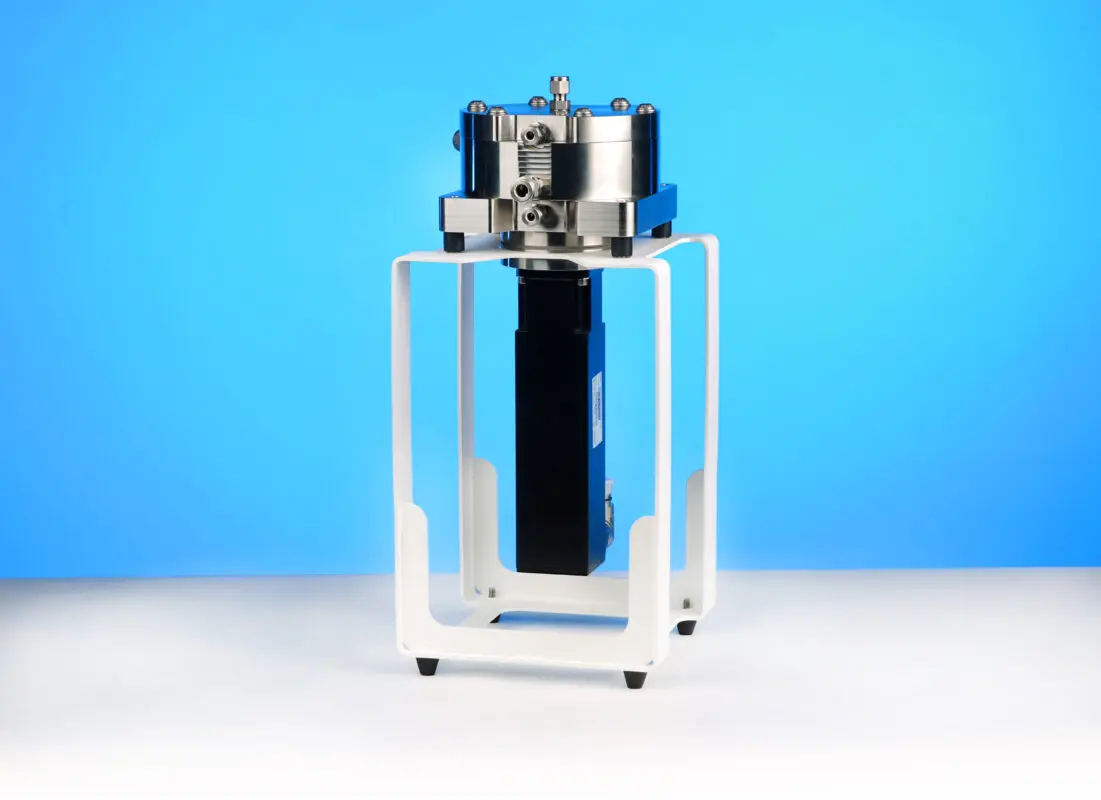

Volume: 15 mL

Stages: 3

Disc speed: 6000 rpm

Max. pressure: 10 barg

Max. temperature: 140 °C

Material: Hastelloy

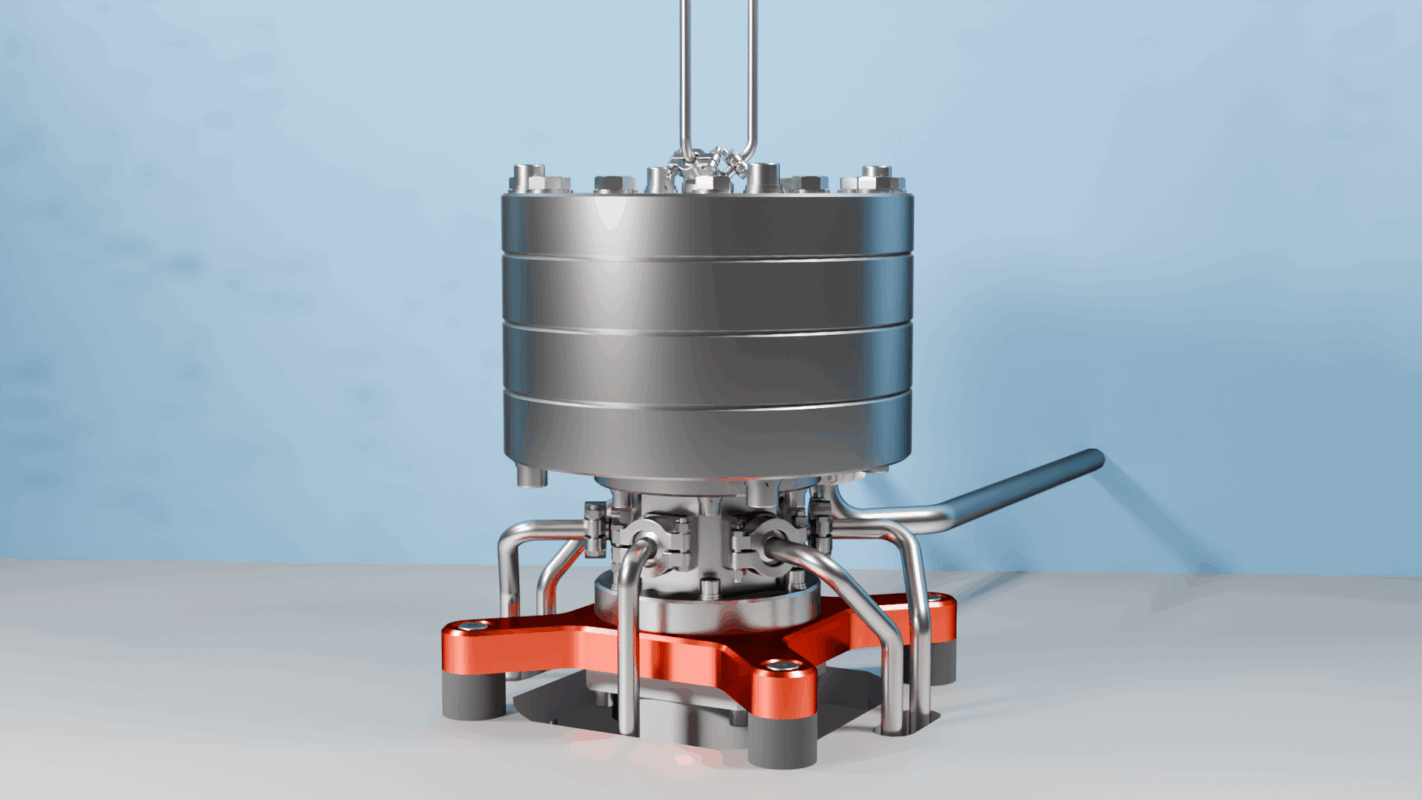

Volume: 135 mL / 230 mL

Stages: 3

Disc speed: 3000 rpm

Max. pressure: 10 barg

Max. temperature: 160 °C

Material: SS316, Hastelloy

Volume: up to 2 L

Stages: 3

Disc speed: 1000 rpm

Max. pressure: 10 barg

Max. temperature: 160 °C

Material: SS316, Hastelloy